TC 250 | 2023

Technical Details

| ENGINE |

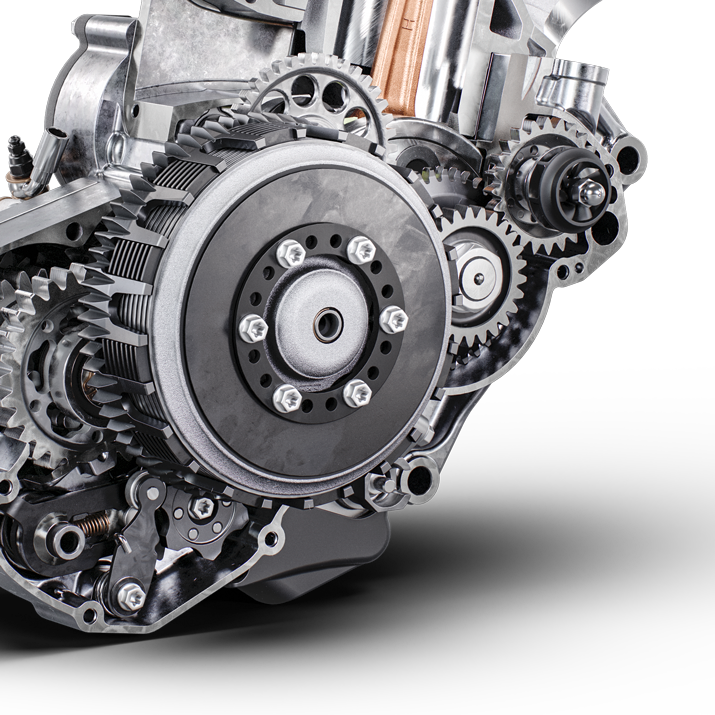

| Transmission |

| 5-speed |

| Battery Capacity |

| 2 Ah |

| Cooling |

| Liquid cooled |

| Starter |

| Electric Starter |

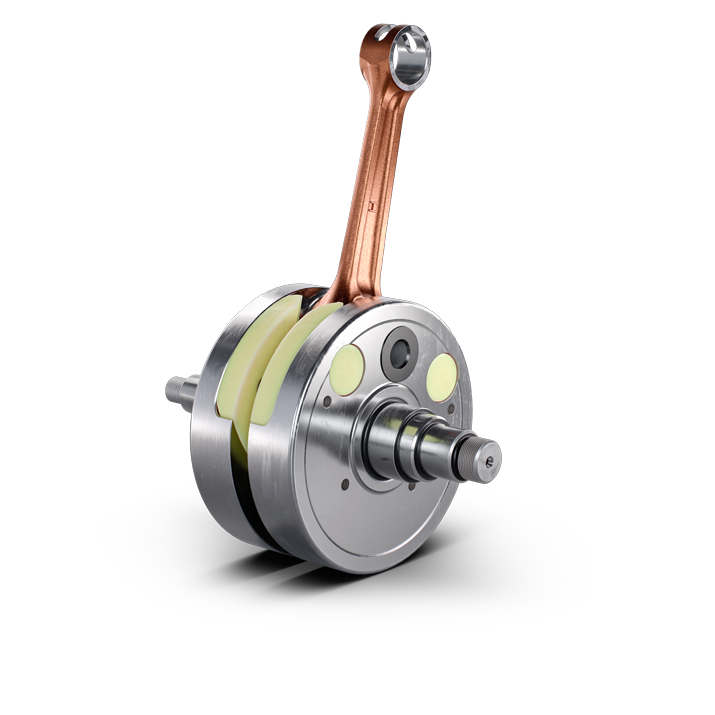

| Stroke |

| 72 mm |

| Bore |

| 66.4 mm |

| Clutch |

| Wet, DDS multi-disc clutch, Brembo hydraulics |

| Displacement |

| 249 cm³ |

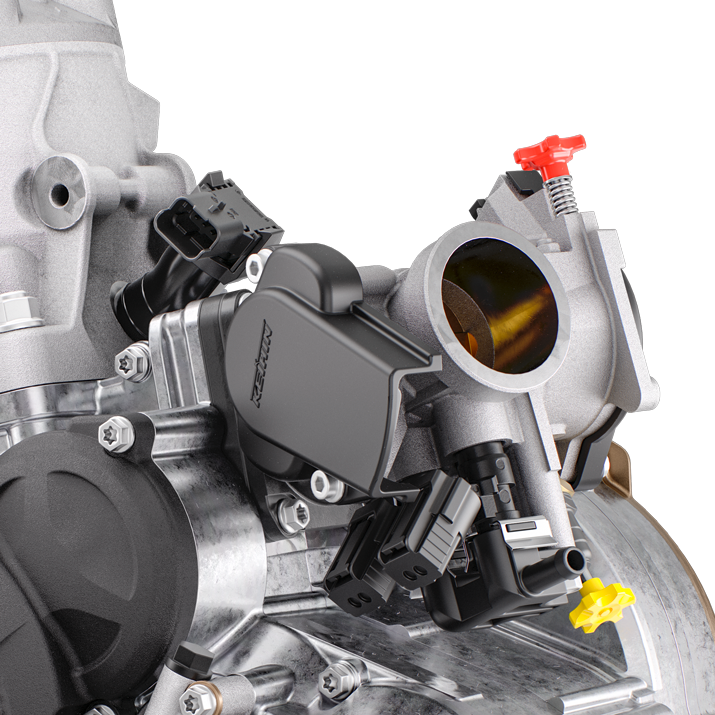

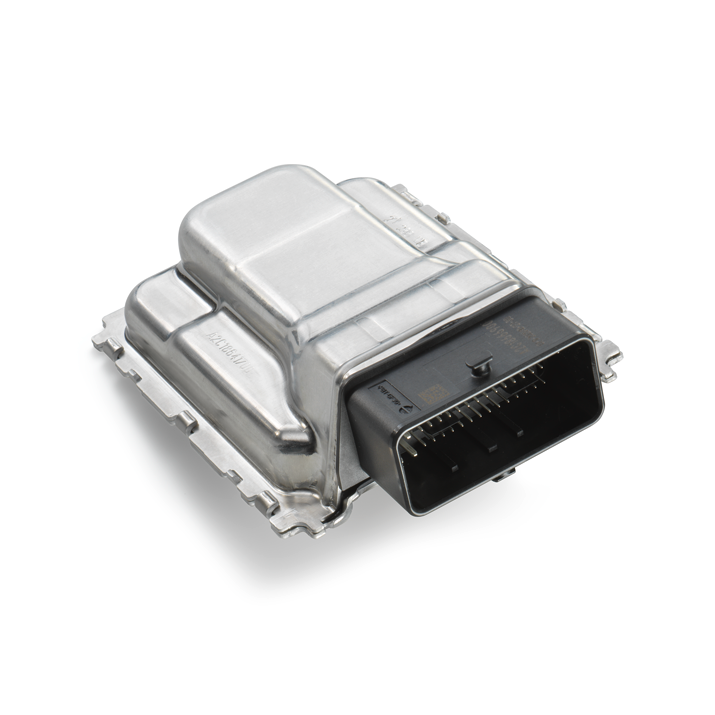

| EMS |

| Vitesco Technologies EMS |

| Design |

| 1-Cylinder, 2-Stroke Engine |

| CHASSIS |

| Weight (without fuel) |

| 99.6 kg |

| Tank Capacity (APPROX.) |

| 7.2 L |

| Front brake disc diameter |

| 260 mm |

| Rear brake disc diameter |

| 220 mm |

| Front brake |

| Disc brake |

| Rear brake |

| Disc brake |

| Chain |

| 520, Non-sealed |

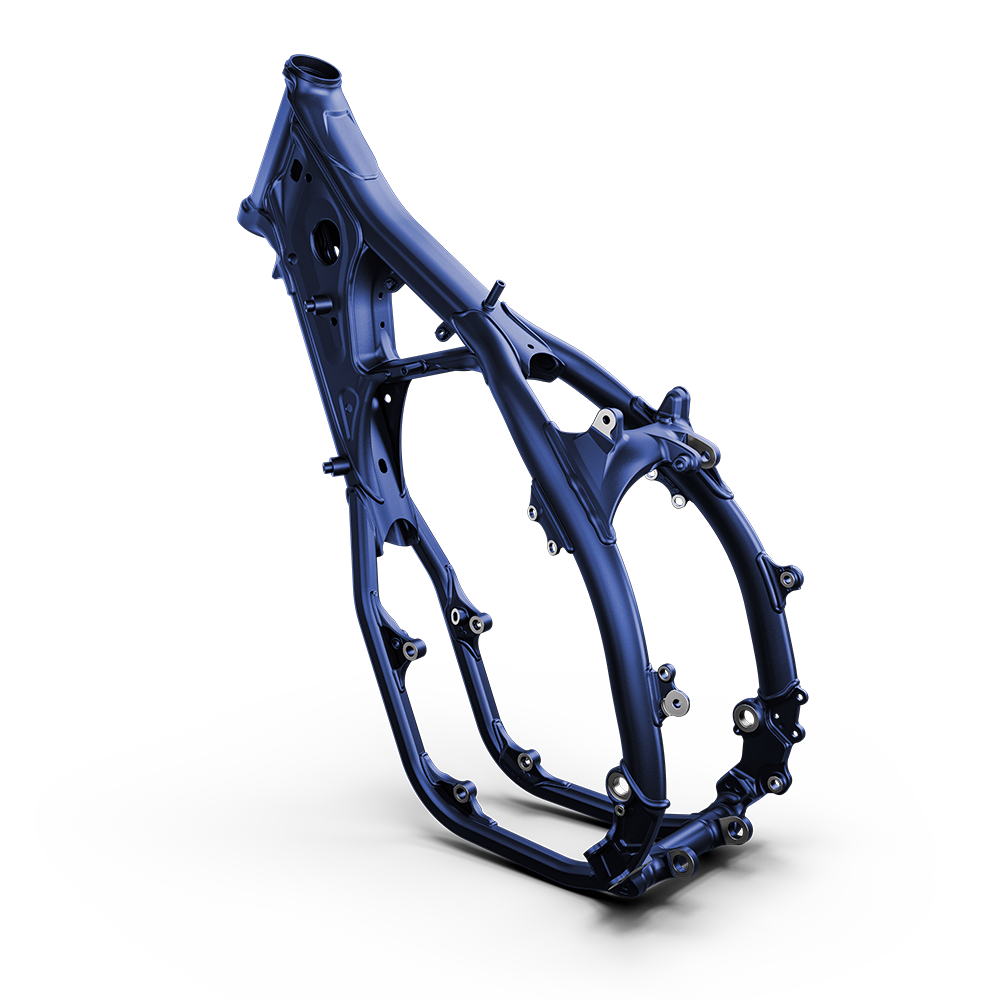

| Frame design |

| Central double-cradle-type 25CrMo4 steel |

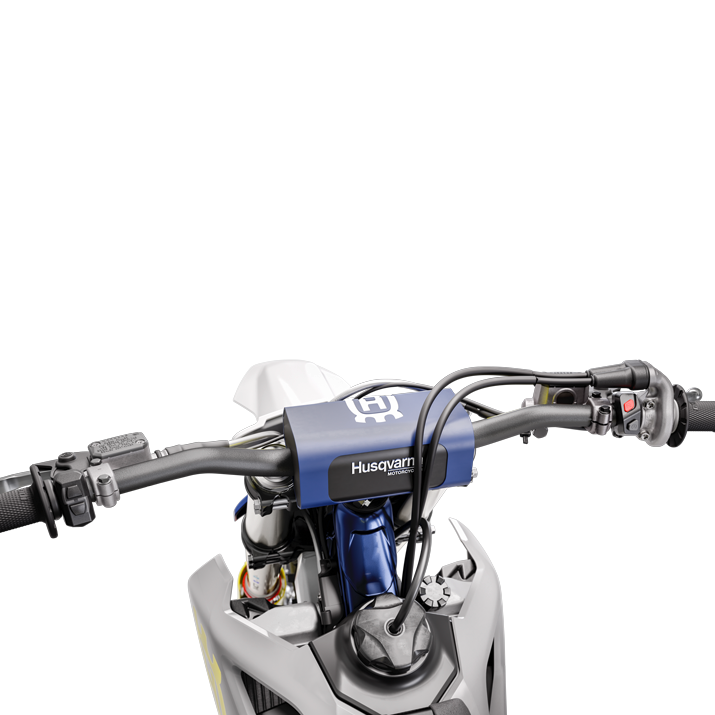

| Front suspension |

| WP XACT-USD, Ø 48 mm |

| Ground clearance |

| 346 mm |

| Rear suspension |

| WP XACT Monoshock with linkage |

| Seat height |

| 939 mm |

| Steering head angle |

| 63.9 ° |

| Suspension travel (Front) |

| 305 mm |

| Suspension travel (Rear) |

| 293 mm |