TC 125 | 2024

Technical Details

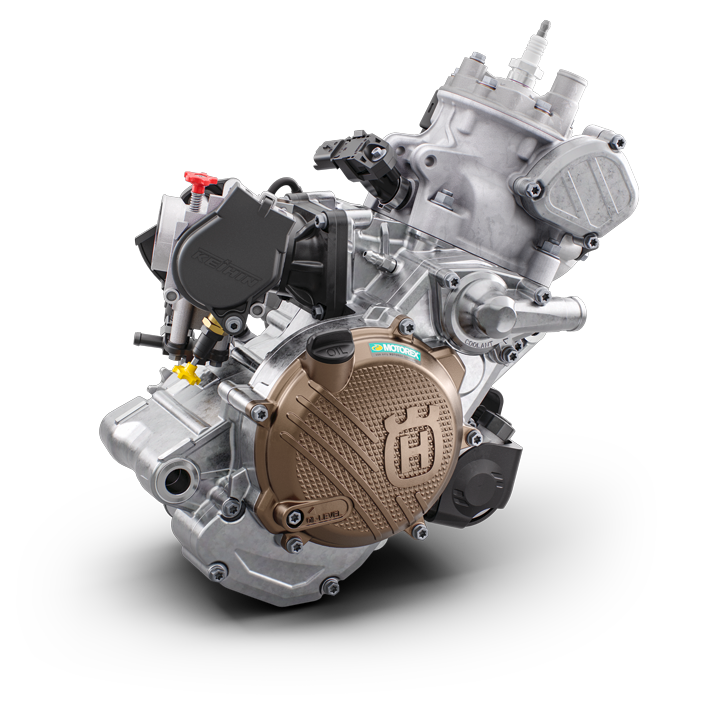

| ENGINE |

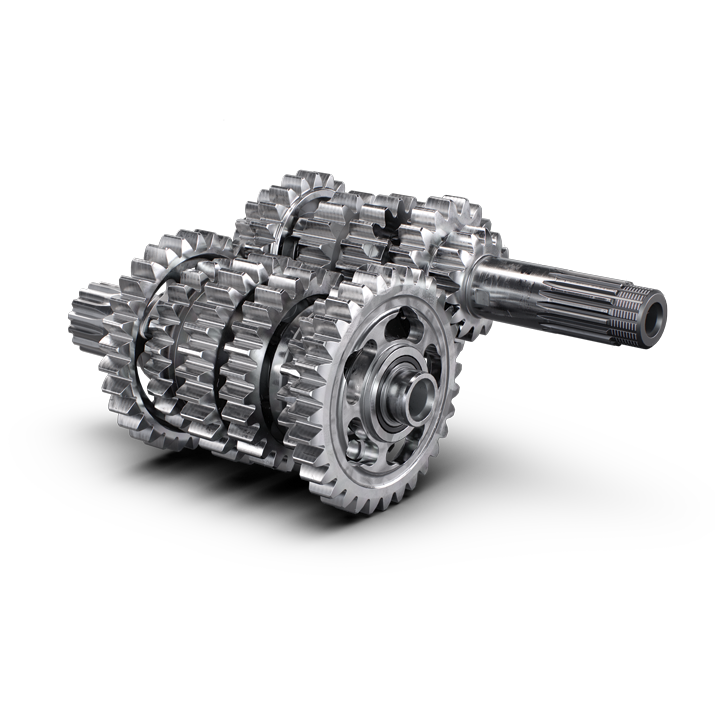

| Transmission |

| 6-speed |

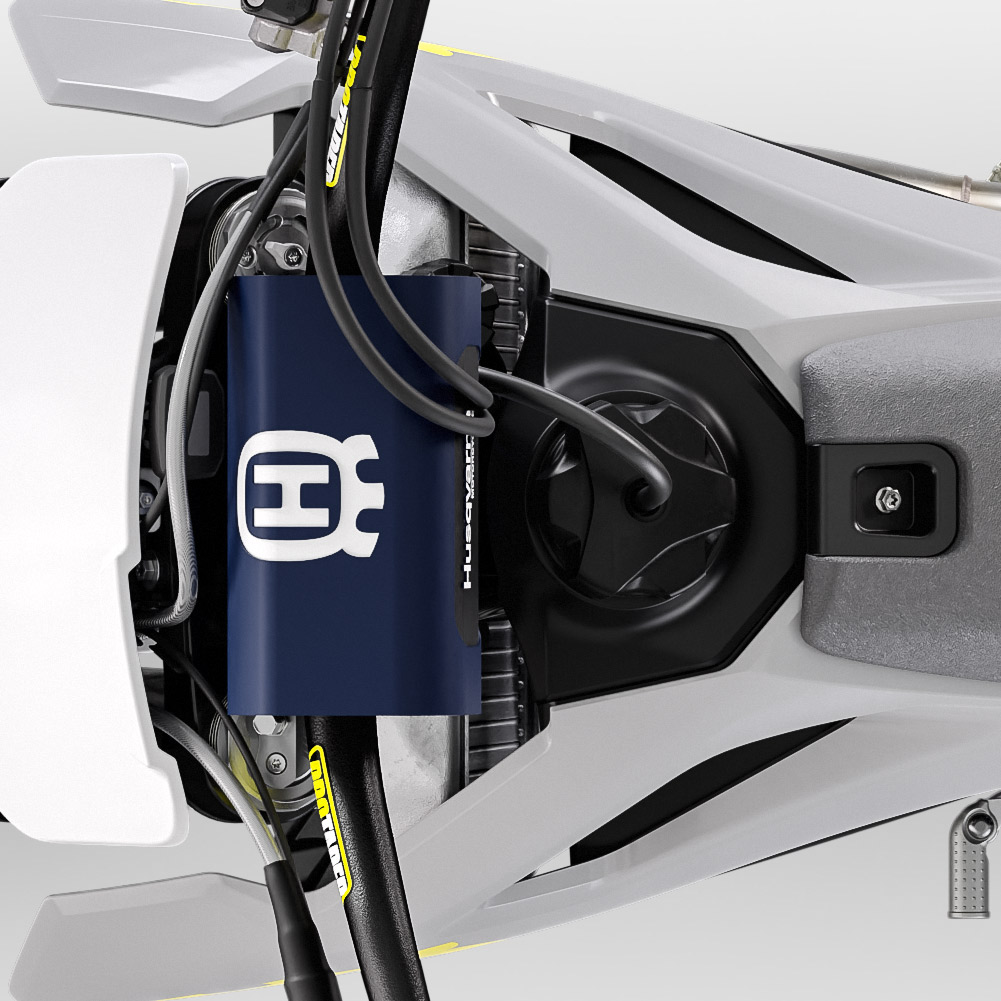

| Battery Capacity |

| 2 Ah |

| Cooling |

| Liquid cooled |

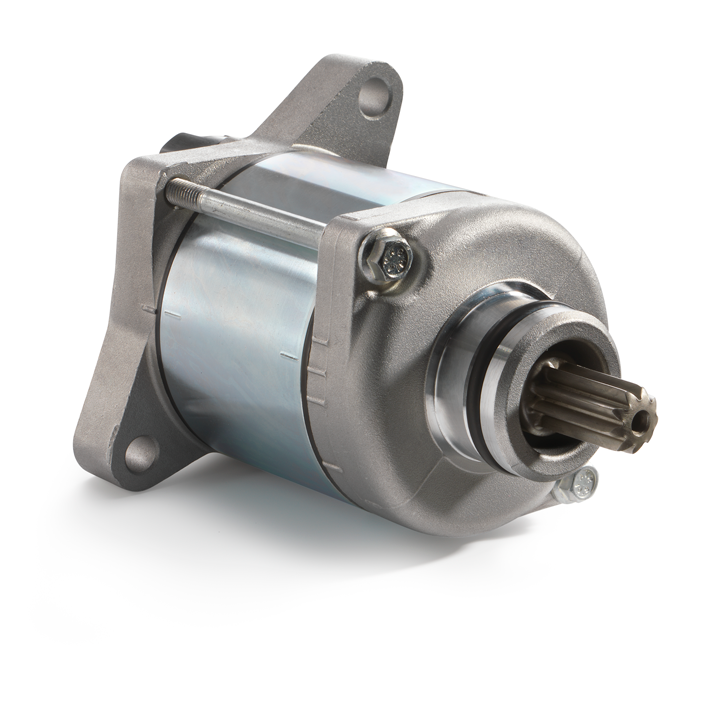

| Starter |

| Electric Starter |

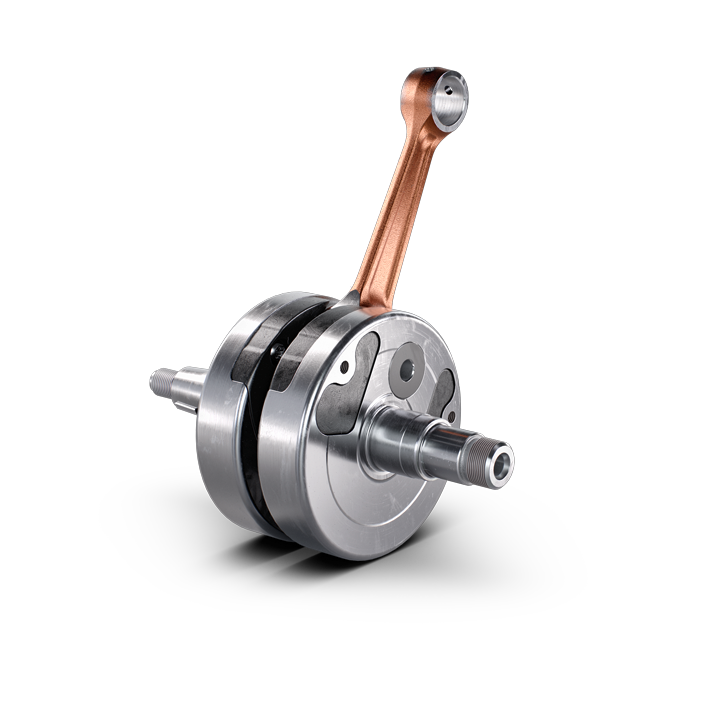

| Stroke |

| 54.5 mm |

| Bore |

| 54 mm |

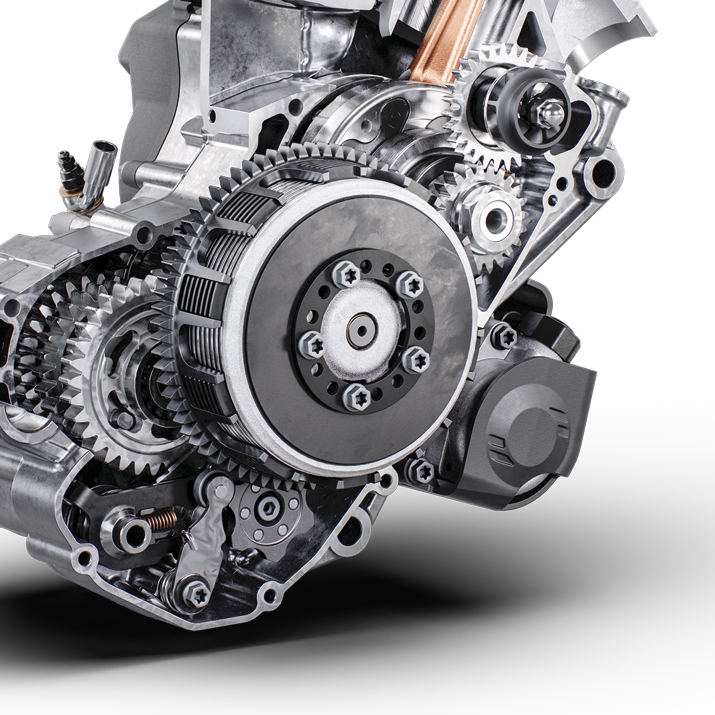

| Clutch |

| wet, multi-disc DS clutch, Brembo hydraulics |

| Displacement |

| 124.8 cm³ |

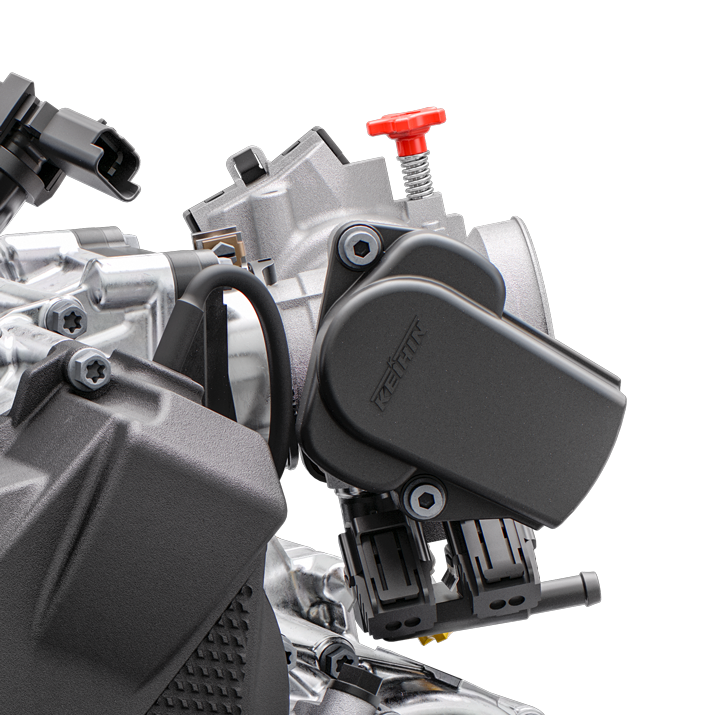

| EMS |

| Vitesco Technologies EMS |

| Design |

| 1-Cylinder, 2-Stroke Engine |

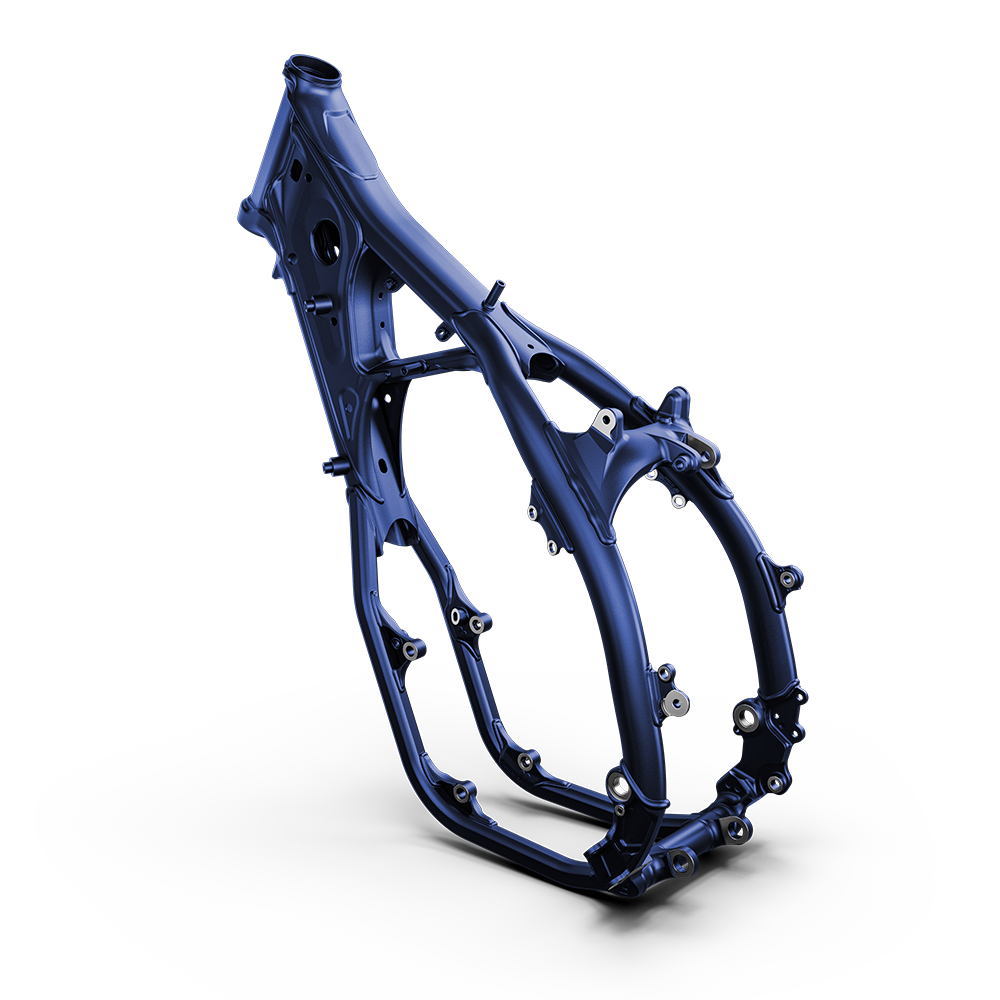

| CHASSIS |

| Weight (without fuel) |

| 92.5 kg |

| Tank Capacity (APPROX.) |

| 7.2 L |

| Front brake disc diameter |

| 260 mm |

| Rear brake disc diameter |

| 220 mm |

| Front brake |

| Disc brake |

| Rear brake |

| Disc brake |

| Chain |

| 520, Non-sealed |

| Frame design |

| Central double-cradle-type 25CrMo4 steel |

| Front suspension |

| WP XACT-USD, Ø 48 mm |

| Ground clearance |

| 350 mm |

| Rear suspension |

| WP XACT Monoshock with linkage |

| Seat height |

| 939 mm |

| Steering head angle |

| 63.9 ° |

| Suspension travel (Front) |

| 305 mm |

| Suspension travel (Rear) |

| 293 mm |