FC 250 | 2024

- Engine

- Engineered to ensure class-leading performance and handling characteristics, all major engine components and shaft arrangements are carefully positioned closer to the centre of gravity to reduce the effects of rotational inertia. The 250 cc 4-stroke engine is also considerably light and tips the scales at just over 26 kg. The FC 250 engine remains remarkably powerful with an increased power output and impressive torque to suit riders of all abilities.

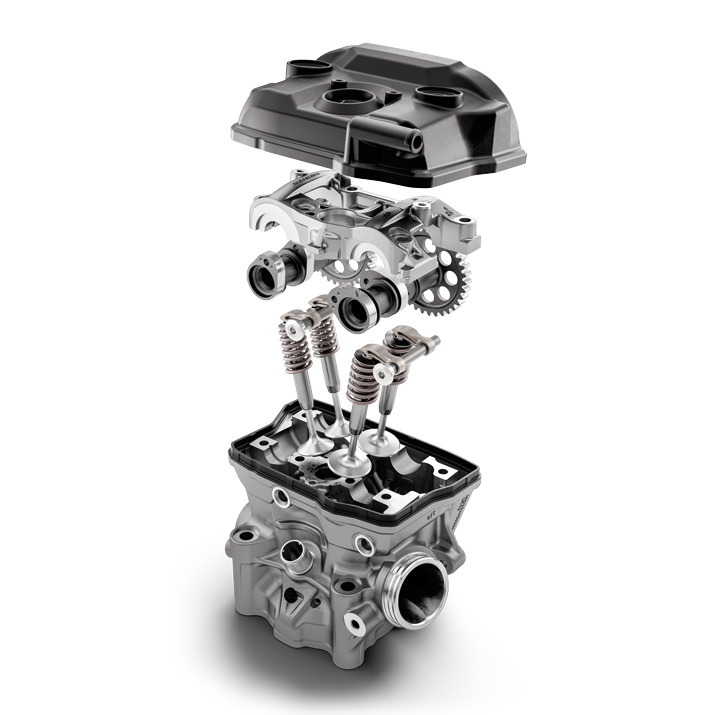

- DOHC cylinder head

- Featuring finger followers treated with a diamond-like carbon (DLC) coating, the DOHC cylinder head is engineered for high-level performance and unrivalled durability. The titanium intake valves are 32.5 mm while the exhaust valves are 27.5 mm for optimised gas flow. The FC 250 revs freely, and produces strong and efficient power throughout the rev range up to its 14,000 rpm limit.

- Cylinder and piston

- The 81 mm cylinder houses a forged bridged-box-type piston made by CP, which weighs just 150 g. High strength aluminium is used to manufacture both the cylinder and piston, with both components professionally engineered for outstanding performance and reliability. The stroke is 48.5 mm to match the resized cylinder, which creates a compression ratio of 14.5:1 for exceptional torque and peak performance.

- Crankcases

- The FC 250 crankcases are designed to optimise mass centralisation by housing all internal components in the ideal position to achieve the perfect centre of gravity. Manufactured using a high-pressure die-cast production process, the result is a thin, exceptionally strong wall thickness at the lowest possible weight.

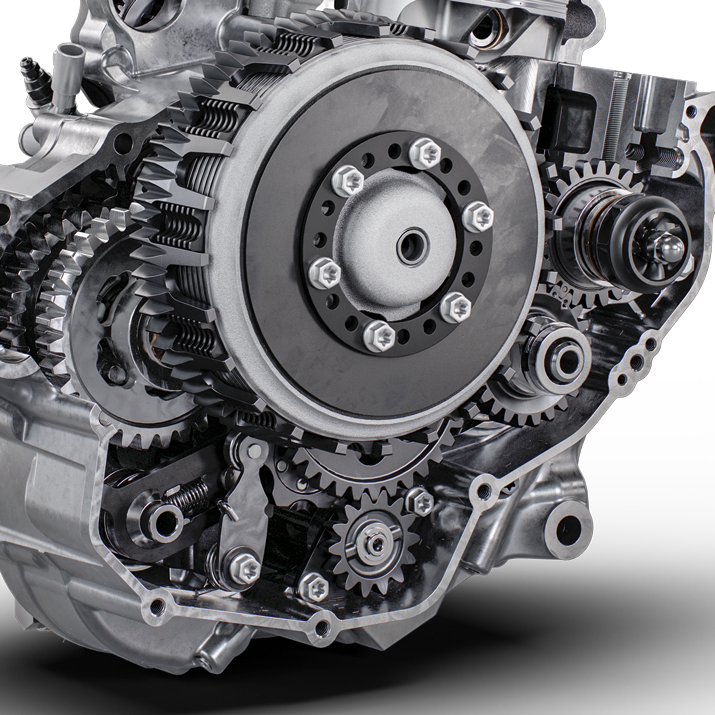

- DS clutch

- The FC 250 features a highly reliable diaphragm steel (DS) clutch. Engineered from a single piece of CNC-machined steel, the clutch basket allows the use of thin steel liners, which contribute to the compact overall design of the engine. Underlining just how strong and durable the clutch is, the same components are used in the much more powerful FC 450.

- Gearbox

- Produced by Pankl Racing Systems, the 5-speed gearbox is designed to be extremely light and durable while featuring optimised and proven motocross-specific gear ratios (24:72). Integrated into the shift drum, a Quickshifter sensor can be activated by pressing the QS marked button on the Map Select Switch to further aid smooth upshifting.

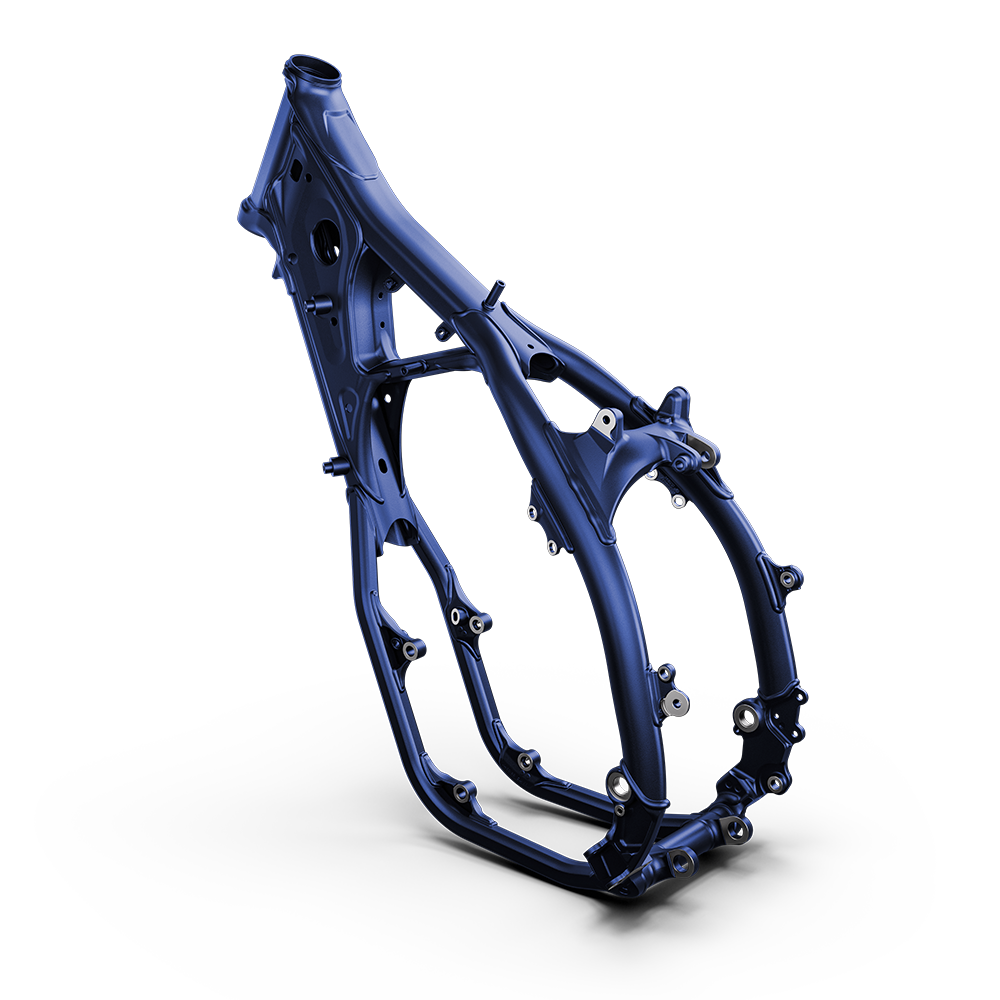

- Lightweight frame

- The proven chromium molybdenum steel frame features optimised wall thickness in all high stress areas for improved reliability and offers advanced geometries and flex characteristics aimed at providing unparalleled rider feedback, energy absorption, and exceptional straight-line stability. The upper shock mounting design - which is not connected to the main tube - significantly improves the anti-squat behaviour of the chassis. The frame is finished off with a premium metallic blue powder coating with standard frame protectors offering superior protection, durability, and grip in any condition. Additionally, the inclusion of forged brackets on the lower frame rails allows for easy installation of the skid plate, which is available as a technical accessory.

- Polyamide-reinforced aluminium subframe

- Made from 60% polyamide and 40% aluminium, the two-piece subframe ensures exceptional strength and durability at an overall weight of just 1.8 kg. The lower subframe spars and frame mounts are manufactured from cast aluminium for significantly improved reliability. The upper section of the subframe is made from injection-moulded polyamide to enable specific flex characteristics and ensure a lightweight construction.

- CNC machined triple clamps

- Working in unison with the frame design and suspension set-up, the CNC-machined triple clamps provide precisely calculated geometry for increased stability. Handlebar flex can be customised with the handlebar clamp, which offers two mounting options - rubber-damped for less vibration, or fixed for enhanced front-end feedback. The upper triple clamp is stiffer to ensure a smoother fork action and plays a vital role in the perfect alignment of the front wheel for superior handling.

- WP XACT front suspension

- New shim stack settings improve the overall balance, cornering agility, and riding comfort on the FC 250 for 2024. The 48 mm WP XACT forks are designed as a closed cartridge system with a capsulated, adjustable air spring and pressurized oil chamber for smooth action and consistent damping. Oil and air bypasses reduce pressure peaks and in combination with a mid-valve damping system, together with a hydrostop that applies a progressive damping force in the last 40 mm of travel, the forks provide precise feedback to the rider. The settings are easily adjusted via the single air pressure pre-load valve, as well as through easy access click adjusters for compression and rebound. Additionally, the air pump needed to adjust the fork's air spring pressure is provided as standard.

- WP XACT shock absorber

- The WP XACT rear shock offers 293 mm of travel. Inside the shock is a computational fluid dynamics (CFD) optimised main piston for improved initial comfort, which provides strong hold-up in all conditions. Differently sized holes in the shims, which feature updated stack settings for 2024 to improve balance and handling, allow them to open more easily which reduces the overall stress of the oil flow. Complete with low friction SKF seals that are fitted throughout the linkage system, consistent damping, comfort, and traction are guaranteed with rebound and both high and low speed compression adjustable by hand.

- Swingarm

- The hollow die-cast aluminium swingarm is manufactured from a single piece of aluminium using an improved die-cast production process for optimal stiffness and a 190 g weight reduction over previous generations. In order to optimise and match the flex characteristics from the frame, a 22 mm rear axle is fitted. Additionally, the chain guard and chain slider have been designed for improved durability and are less prone to catching on external objects.

- Functional bodywork

- Clean, Swedish-inspired styling and ergonomics are designed to allow riders to perform at their very best for extended periods of time. Following countless hours of testing and refinements, the contact points and surfaces in the rider triangle enhance comfort, which in turn helps to reduce fatigue. A flat seat offers unrestricted movement with a high grip cover ensuring riders stay firmly in place under hard acceleration.

- Airbox

- Designed with precisely positioned inlet ducts aimed at reducing drag and air flow deformation, the airbox ensures unrestricted airflow with maximum filter protection. The Twin Air filter is easily accessed without tools, by simply removing the left side panel for easy maintenance. Offering further performance customisation, the FC 250 is delivered with an additional airbox cover that can be changed without the use of any tools for a sharper throttle response based on rider preference or track conditions.

- Hydraulic clutch

- The high-performance Brembo hydraulic clutch system guarantees even wear, near maintenance-free operation, and perfect action in every condition. With this hydraulic system, free play is constantly compensated so that the pressure point and function of the clutch remain identical in cold or hot conditions, as well as over time. Countless hours of race-focused testing have proven the exceptional reliability of the high-quality, Italian-made Brembo hydraulic systems.

- Hydraulic brakes

- The highest level of quality is guaranteed as the class-leading Brembo brake callipers are made from single pieces of aluminium for exceptional strength at the lowest possible weight. Together with a 260 mm front and a 220 mm rear disc, which are designed to prevent mud build-up, superior stopping power and braking confidence is guaranteed in all conditions.

- ProTaper handlebar

- Developed between Husqvarna Motorcycles and leading handlebar manufacturer, ProTaper, the exclusive bend offers superior comfort, class-leading strength, and fatigue resistance at the lowest possible weight.

- ODI grips

- ODI lock-on grips feature an innovative, integrated throttle mechanism and are installed without using glue. The throttle assembly offers easy free-play adjustment with the option to fit alternative cams for a personalised throttle action.

- Footrests

- The CFD-designed footrests are extra wide to ensure better control of the machine while at the same time are less susceptible to catching on deep ruts, take-offs when scrubbing, and trackside barriers. This is achieved by a narrower mounting design in the frame layout, which also helps reduce overall weight.

- Wheels and tyres

- Assembled with CNC-machined hubs, lightweight spokes, and strong, black-anodised alloy rims by Excel Takasago, the wheels of the FC 250 are then fitted with Dunlop Geomax MX33 Motocross tyres, which feature a proven block-within-a-block design for more progressive cornering and superior grip. For improved on-track agility, the 110/90-19 rear tyre and 80/100-21 front tyre ensures optimal handling on a variety of riding surfaces.

- Exhaust system

- Manufactured from lightweight aluminium, the exhaust system on the FC 250 features a flow-designed resonance chamber that is integrated into the header pipe. The silencer has a short and compact design, delivering impressive power output while keeping decibels as low as possible. A black coating highlights the premium quality of the silencer.

- Cooling system

- Manufactured from high-strength aluminium, the radiators are designed using computational fluid dynamics (CFD) to channel air through them in the most effective way. A large centre tube through the frame reduces pressure at this point in the system for a consistent coolant flow while an internal thermostat further enhances reliability.

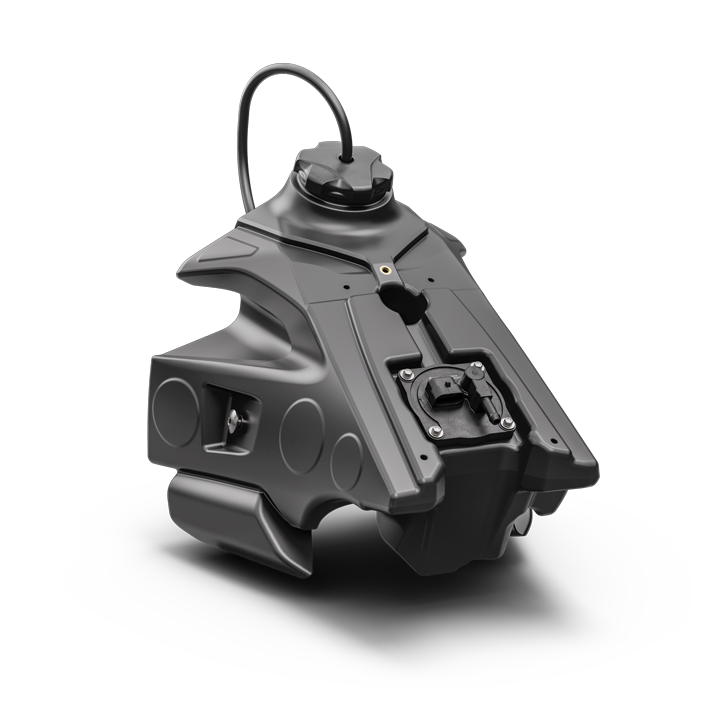

- Fuel tank

- A 7.2 litre fuel tank integrates neatly with the ergonomic bodywork. The fuel pump design and location allows the tank to be emptied further, which is particularly beneficial for longer races. For improved durability, the external fuel line is specifically routed to make it less exposed and susceptible to damage.

- Map select switch

- The intuitive handlebar-mounted Map Select Switch allows riders to activate Launch and Traction Control, enable the Quickshifter, and allows riders to toggle between two engine maps. The easy-to-operate Map Select Switch allows racers to quickly alter and set up the engine characteristics on a race by race basis dependent on track conditions and rider preference.

- Quickshift

- The Quickshifter can be activated or deactivated via the Map Select Switch and works by interrupting the ignition for a fraction of a second when upshifting. A sensor on the shift drum registers the force from the shift lever, sends a signal to the ECU, and ensures smooth gear changes - even when the throttle is fully open. To prevent unintended shifts and false neutrals, the function is only active from second gear upwards.

- Traction Control

- Traction Control on the FC 250 is engaged by pressing the button marked 'TC' on the Map Select Switch and functions by analysing throttle input from the rider and the rate at which engine RPM increases. If the RPM increases too quickly, the engine management system (EMS) registers a loss of grip and reduces the amount of power to the rear wheel to ensure maximum traction. This is a distinct advantage in wet or muddy conditions.

- Launch Control

- With the engine at idle, Launch Control is engaged by pressing the Traction Control and Quickshifter buttons simultaneously. Both symbols will start flashing to indicate that Launch Control is active. This function limits the amount of power to the rear wheel, improving traction, and preventing loss of control under hard acceleration. Once a gear change is made, the Launch Control will deactivate automatically. Additionally, the Quickshifter function is deactivated when Launch Control is engaged.

- Mapping

- For personalised power delivery, the FC 250 has two built-in engine maps as standard. Map 1 (white) offers linear, predictable power, while map 2 (green) is more aggressive for sharper throttle response and more explosive power output.

- EMS

- The engine management system (EMS) is designed to be small, light, and fast at processing data. It incorporates a rollover sensor (ROS) which cuts the ignition and shuts off the engine in the event of a severe crash for an additional layer of safety.

- Hour meter

- The hour meter comes with an integrated fuel level indicator, which is visible on the FI status LED, and warns the rider when the fuel level is getting low.

- Start/stop switch

- The combined start/stop switch is located on the right side of the handlebar for easy, thumb-operated use. Not only simplifying the starting and stopping of the engine, the removal of a designated stop only button from the handlebar reduces the risk of potential damage or activation in the event of a fall.

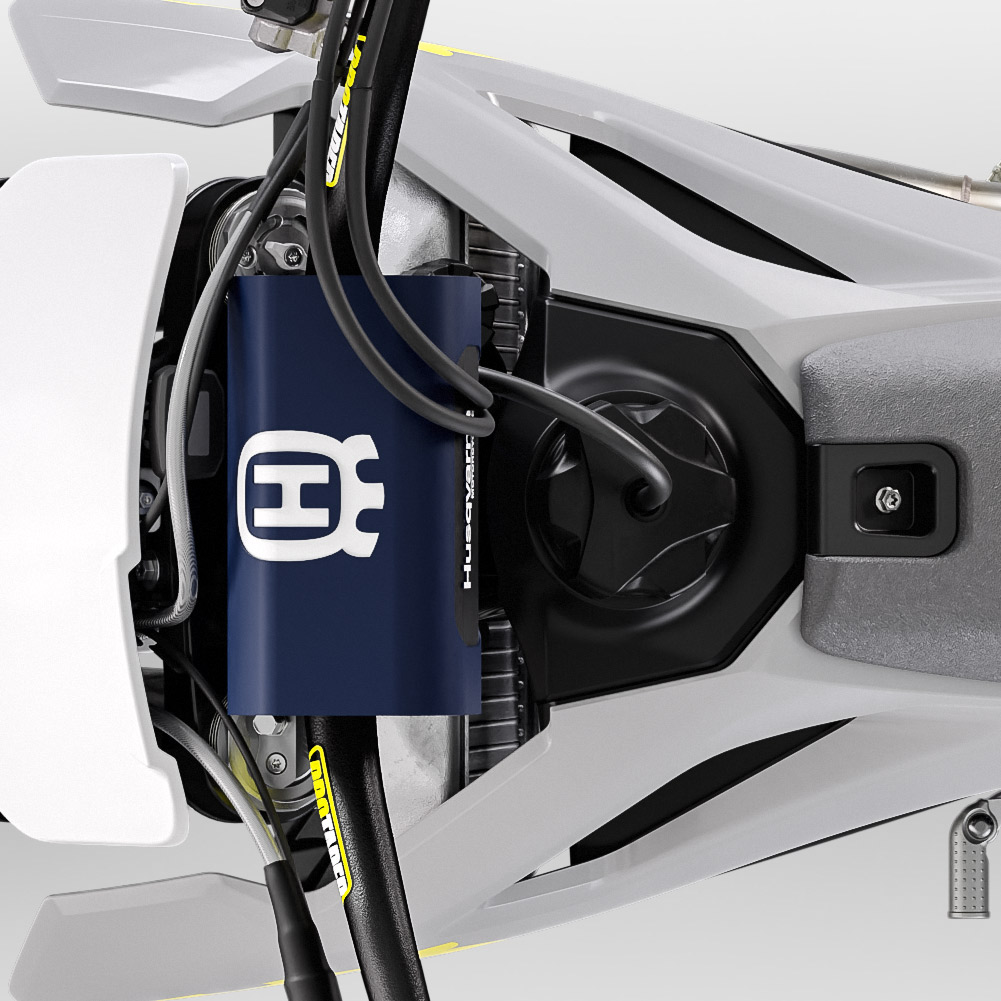

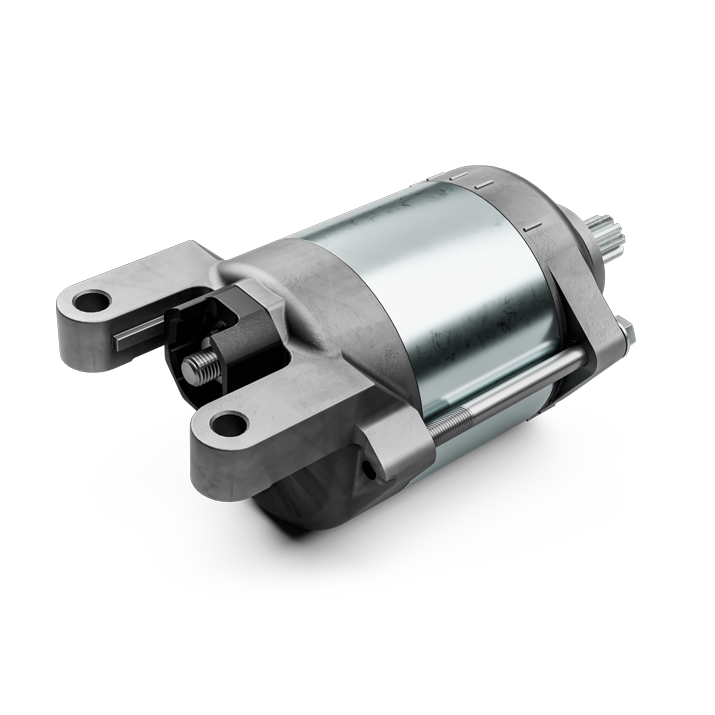

- Electric start

- The convenience of a lightweight starter motor and compact battery set-up means starting the motor, or recovering from a stall effortlessly, is as simple as a push of a button.

Technical Details

| ENGINE |

| Transmission |

| 5-speed |

| Battery Capacity |

| 2 Ah |

| Cooling |

| Liquid cooled |

| Starter |

| Electric Starter |

| Stroke |

| 48.5 mm |

| Bore |

| 81 mm |

| Clutch |

| Wet multi-disc DS clutch, Brembo hydraulics |

| Displacement |

| 249.9 cm³ |

| EMS |

| Keihin EMS |

| Design |

| 1-Cylinder, 4-Stroke Engine |

| CHASSIS |

| Weight (without fuel) |

| 101.2 kg |

| Tank Capacity (APPROX.) |

| 7.2 L |

| Front brake disc diameter |

| 260 mm |

| Rear brake disc diameter |

| 220 mm |

| Front brake |

| Disc brake |

| Rear brake |

| Disc brake |

| Chain |

| 520, Non-sealed |

| Frame design |

| Central double-cradle-type 25CrMo4 steel |

| Front suspension |

| WP XACT-USD, Ø 48 mm |

| Ground clearance |

| 336 mm |

| Rear suspension |

| WP XACT Monoshock with linkage |

| Seat height |

| 939 mm |

| Steering head angle |

| 63.9 ° |

| Suspension travel (Front) |

| 305 mm |

| Suspension travel (Rear) |

| 293 mm |